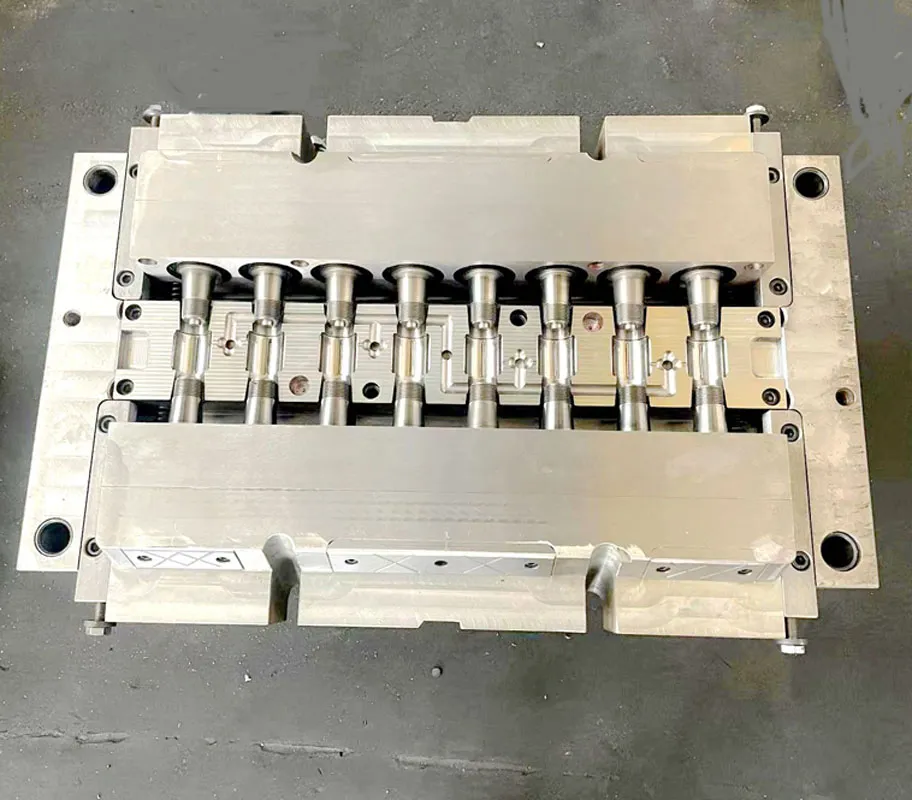

UPVC Reducing Tee Pipe Fitting Mould

Mould name: UPVC Reducing Tee Pipe Fitting Mould

Cavity: 2 cavities

Mould size:110x75

Mould steel:Germany2316 china2316 or4cr13 for the cavity and core

Gate :direct gate

mould structure:Angle pin

Hardness of core/cavity: HRC 40-45°degree after vaccum heat treatment

UPVC Reducing Tee Pipe Fitting Mould machine: 250T

Following is the main information for your reference.

1、 Requirements of UPVC material characteristics for demolding system

Before designing a demolding system, it is necessary to understand the unique properties of UPVC (especially soft UPVC):

Poor thermal stability: prone to decomposition at high temperatures, releasing corrosive gases (HCl), therefore requiring short flow channels, fast cooling, and avoiding retention.

Elasticity and viscosity: Soft UPVC has certain elasticity and viscosity, which may cause the product to be tightly wrapped around the core, resulting in high demolding resistance.

Wide range of hardness: from hard UPVC (such as water pipes) to soft UPVC (such as hoses and sealing strips), their shrinkage rate and demolding behavior are different.

May not use release agents: To avoid contamination and affect subsequent processing (such as printing and bonding), it is usually preferred to achieve smooth release through mold design rather than relying on release agents.

Therefore, the demolding system of UPVC molds must operate reliably, have sufficient force, and avoid excessive local stress that may cause product deformation or tearing.

2、 The core components of the demolding system

A typical UPVC mold demolding system mainly consists of the following parts:

1. Top out mechanism

This is the part that provides demolding power.

Top rod (top pin): The most commonly used component. Usually installed on the top needle plate and pushed by the top rod of the injection molding machine.

Push out stroke: It is necessary to ensure that the product can be completely pushed out of the core and have an appropriate safety margin.

2. Top out components

The part that directly contacts the product and pushes it away from the mold.

Dome needle: the most universal, easy to manufacture, and convenient to replace. Suitable for most flat or slightly curved areas.

Flat top needle: used for demolding deep and narrow reinforcement ribs (bone positions), which can provide a larger contact area and prevent top penetration or whitening.

Sleeve top pin (driver's pin): used for demolding around core screws or cylindrical structures. It consists of an outer cylinder and an inner needle, with the outer cylinder ejecting the product and the inner needle supporting the core.

Top block: For large, deep cavity or thin-walled products, using a top block can provide a large and flat top force surface, avoiding local stress concentration and top whitening of the product. This is very common in UPVC molds.

Air cap (air valve): Use compressed air to assist in demolding. Especially suitable for:

Products with deep cavities and high demolding resistance.

Soft PVC products, due to their elasticity, can be expanded and separated from the core by air pressure.

As the primary demolding action, break the vacuum adsorption between the product and the core.

Procedure of mould making

Step 1 place the order & receive the down payment

Step 2 Design and make the drawing( products& moulds)

Step 3 Customer check & confirm

Step 4 Steel material purchase

Step 5 Machine process(CNC, sparking machine, boring machine) & mould makers install

Step 6 Mould testing

Step 7 Send the samples to check

Step 8 Receive the balance & mould shipment

Packaging and transportation

1. UPVC Reducing Tee Pipe Fitting Mould: after the mould is assembled and cleaned, apply antirust fog or antirust grease on the mould, then cover it with film and put it into a stable wooden box.

2. for plastic products: first use semi transparent thin foam plastics to wrap each part in plastic bags, and the second step is to put the thin sponge board into the carton to prevent scratches.

Our services

Pipe mold: UPVC water supply and drainage pipe mold p

PPR pipe fitting mould/PE pipe fitting mould/PPSU pipe fitting mould /Pp-h and PVC flaring pipe mould/Mould for electrical pipe fittings /Mould for UPVC pipe fittings/Mould for irrigation pipe fittings/Mould for plastic ball valve pipe fittings

Design of mold cooling system

The design of cooling system is a complicated work, that is to design a good cooling effect and consider the uniformity of cooling, and also consider the influence of cooling system on the overall structure of the mold, the specific location and size of the cooling system are determined; Main consideration is cooling of moving die or insert; Cooling of side slide block and side core; Design of cooling elements and selection of cooling standard elements.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED